Whether it’s backed-up drains, foul smells, or something else, repairing a damaged sewer line is something that needs to be taken care of immediately. Slow drains prevent you from using appliances, foul smells are simply unpleasant, and uncontained waste can create even more severe problems. This Lynn, Massachusetts customer called for Permanent Pipe Lining from Spencer Home Services to completely repair their sewer line.

Homeowners should repair a compromised sewer line to avoid all of the above issues. However, by opting for Spencer Home Service’s Permanent Solution Pipe Lining, homeowners can enjoy the following benefits:

- Extremely long-lasting thanks to the incredibly hard epoxy coating.

- Pipelining is more convenient due to the lack of excavation.

- More efficient due to the lack of digging needed.

- Cheaper than traditional methods due to less involvement from heavy equipment and manpower.

- More effective than traditional methods because the epoxy liner hardens to strengthen the existing pipe, stronger than it was previously.

PERMANENT PIPE LINING VS. OTHER SEWER LINE REPAIR METHODS

To repair a damaged sewer line, homeowners have a couple of options. The two biggest differentiators between them are whether they are trenchless sewer repairs or traditional excavation and replacement. Traditional sewer repair involves digging up the foundation, lawn, or whatever is above the affected sewer line. With trenchless sewer lining, Spencer Home Services is able to repair damaged sewer lines through an access point. That means no digging or excavation of your property. For most, it’s a relatively easy choice so long as trenchless lining is available.

BENEFITS OF PERMANENT PIPE LINING SEWER LINE REPAIR

Permanent sewer pipe lining typically involves the installation of a new, seamless pipe liner within the existing damaged sewer pipe. This liner is highly durable and resistant to cracking, root intrusion, and other common issues that can occur with traditional sewer pipe materials.

WHEN PERMANENT PIPE LINING CAN’T BE TRENCHLESS

There are several instances where a sewer lining repair may have to be dug up to apply the lining instead of applying it via trenchless methods. Some of these instances include:

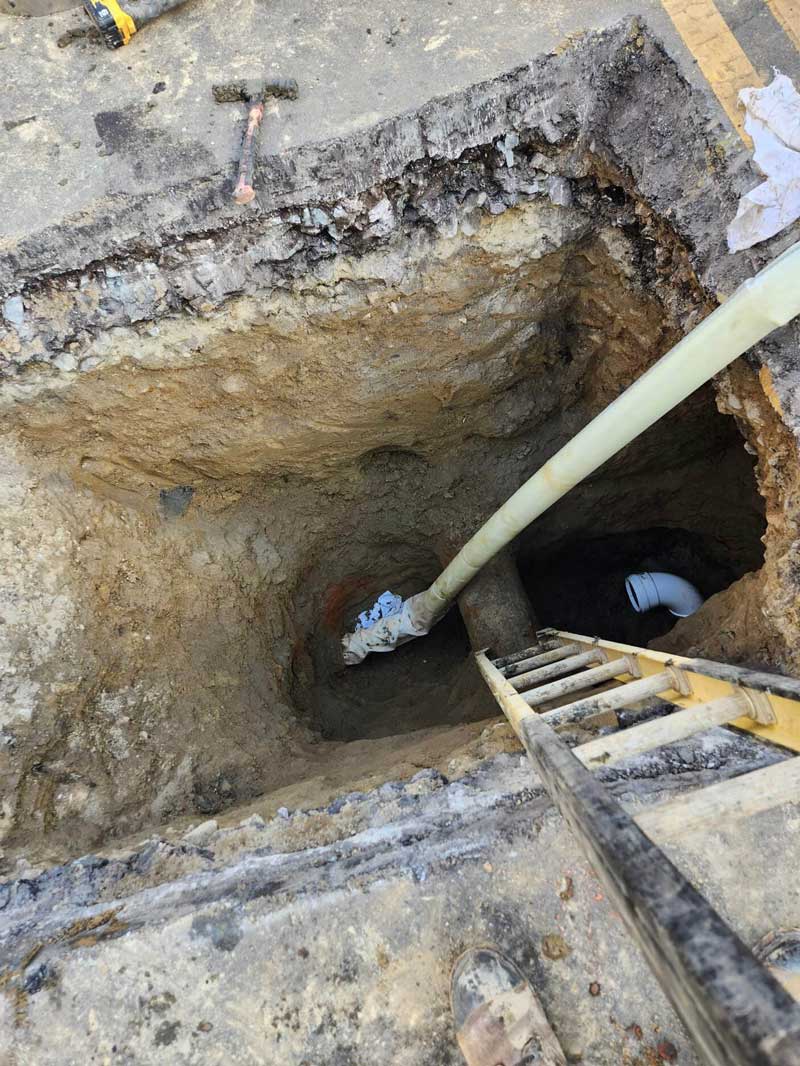

- Damage to the Sewer Line: If the sewer line has extensive damage, such as collapsed or severely cracked sections, it may not be possible to apply a sewer lining using trenchless methods. In such cases, it may be necessary to excavate the damaged section and replace it with a new pipe before applying a new sewer lining. In this case, the customer had a severe crack that required replacement of the affected section. Permanent sewer pipe lining strengthened the rest of the pipe preventing future issues.

- Incorrect Pipe Size or Material: Trenchless methods are generally suitable for repairing pipes of the same size and material. If the pipe size or material is incorrect, it may not be possible to apply a sewer lining using trenchless methods. In such cases, excavation may be necessary to replace the pipe with the correct size or material before applying a new sewer lining.

- Obstructions in the Sewer Line: Trenchless methods require unobstructed access to the sewer line. If there are obstructions, such as large rocks or debris, it may not be possible to apply a sewer lining using trenchless methods. In such cases, excavation may be necessary to remove the obstructions before applying a new sewer lining.

- Limited Access: Trenchless methods require access to the sewer line from both ends. If there is limited access, such as in a narrow alleyway or a backyard with limited space, it may not be possible to apply a sewer lining using trenchless methods. In this case, the affected section was on the road where there was no access point.

In summary, while trenchless methods are generally preferred for sewer lining repair due to their efficiency and cost-effectiveness, there are situations where excavation may be necessary to apply permanent sewer pipe lining. The decision to use trenchless or excavation methods will depend on the specific circumstances of each repair project.

PERMANENT PIPE LINING PROCESS IN LYNN, MA

ACCESS AND MAP THE PIPING SYSTEM WITH A VIDEO INSPECTION

The first step in any sewer lining repair job is to get a clear understanding of the problem. To do this, we used a video inspection camera to access and map the piping system. This allowed us to identify the location of any blockages, cracks, or other damage to the sewer line.

OBTAIN ALL NECESSARY PERMITS AND INSPECTIONS

As with any construction project, sewer lining repair jobs require permits and inspections to ensure that the work is done safely and in compliance with local regulations. Spencer Home Services took care of all the necessary paperwork and inspections to ensure that the job was done right.

THOROUGHLY CLEAN THE PIPE OF ROOTS AND ALL DEBRIS

Once we had a clear understanding of the problem, we began the cleaning process. We used specialized tools to remove any roots, debris, or other blockages that were preventing the flow of water through the sewer line. This step is crucial to ensure that the new liner will adhere properly to the existing pipe.

INSERT THE RESIN-SATURATED LINER INTO THE HOST PIPE

With the pipe cleaned and prepped, we were ready to insert the new liner. The liner is made of a felt-like material that is saturated with a resin that will harden once it’s in place. We carefully inserted the liner into the host pipe and made sure that it was positioned correctly.

INSTALL A FULL-LENGTH EPOXY LINER

Once the liner was in place, we used air pressure to inflate it and press it firmly against the walls of the host pipe. This ensured that the epoxy liner would form a tight bond with the existing pipe and create a seamless, jointless lining.

ALLOW THE LINER TO HARDEN USING THE CURED-IN-PLACE-PIPE (CIPP) PROCESS

The epoxy liner we used is cured using a process known as Cured-In-Place-Pipe (CIPP). This involves using hot water or steam to activate the resin and harden the liner. We carefully monitored the curing process to ensure that the liner was fully hardened and ready for use.

INSPECT THE PIPE TO ASSURE A SMOOTH, JOINTLESS LINING

Once the liner was fully cured, we used a video inspection camera to inspect the pipe and ensure that the new lining was smooth and jointless. This step is critical to ensure that the new liner will function properly and provide a long-lasting solution.

REMOVE ALL DEBRIS FROM THE SITE

Finally, we removed all debris from the job site and made sure that the area was clean and free of any hazards. We take pride in our work and strive to leave every job site better than we found it.

PERMANENT PIPE LINING SOLUTIONS IN LYNN, MA

At Spencer Home Services, we provide high-quality sewer lining repair services to homeowners and businesses in Lynn, Massachusetts and the surrounding areas. If you’re experiencing sewer line problems or have any questions about our services, please don’t hesitate to contact us. We’re here to help!